BV-scan

BV-Scan measures the railbed profile using a scanning laser that can be mounted on almost any railroad machine.

BV-Scan measures sections of the railbed while the machine is moving. Other work, such as plowing, can be performed at the same time. The measured profiles are shown on a computer display and are stored in the computer to be presented as reports later.

BV-Scan can be mounted on almost all kinds of railroad machines and engines. Mobile Robotics can adapt BV-Scan to fulfill your specific needs and applications. A number of optional add-ons are already available.

Functionality

The heart of the system is a scanning range measuring laser. The laser is mounted at a high position to achieve a wide field of view; on top of the cabin or on a separate pillar depending on the machine type.

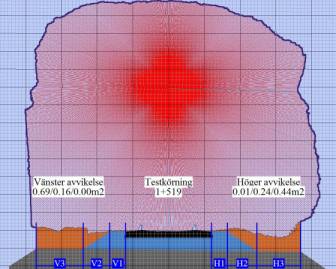

The laser looks downward scanning a 180 degree sector and measures the distances to the ballast and objects in the field of view. The result is a cross section of the railbed profile which is presented graphically on a display.

The measured profiles are stored in a computer and can be used to generate reports. The software calculates the total ballast surplus and deficit based on the measurements. The operator decides at what interval the section measurements are to be performed.

The image below show the operator interface. The displayed profile is continouosly updated.

Hardware

- Laser scanner with 180 degree field of view.

- Weather proof casing with ventilation and dust protection.

- Inclinometer

- Rail sensors measures the suspension movement and tilt.

- Odometer for the positon along the track.

- Control panel with controls, indicator lights and buzzer.

- USB connected laptop PC computer.

Software

BVScan

BVScan is used to collect the measurements and store them for reporting. It can also show the profiles while measuring allowing the operator of the machine to adjust the operations based upon the laser measurements.

BVEdit

BVEdit is used to view and edit the measurements offline. It also includes powerfull reportgeneration capabilities.

A special version of BVEdit - BVReport - is available for distribution to customers. It includes the viewing and report generation of BVEdit but do not allow data to be edited.

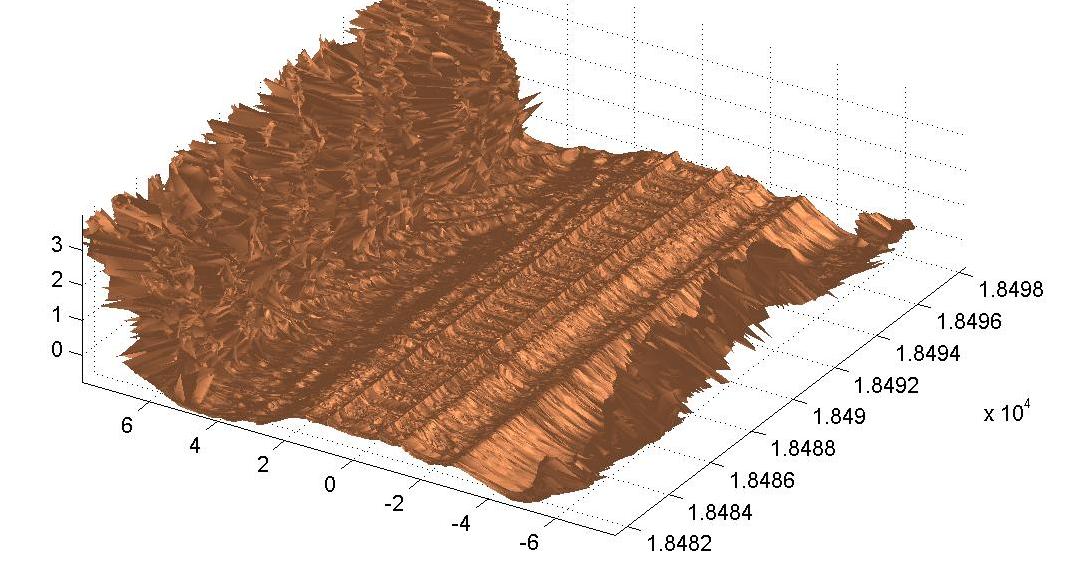

Railbed high resolution option

For the railbed high resolution option an additional high speed high resolution laser scanner is mounted lower on the vehicle about 150cm above the track. This scanner allows the railbed to be inspected and documented with centimeter resolution at high working speeds (35km/h for full resolution).

The high resolution scanner is removable and one scanner can be moved between different BV-Scan equipped vehicles.

The high resolution scanner is especially useful for inspecting the railbed level between sleepers on high speed tracks where excess ballast can cause damages. It's also useful when using the 3D option to inspect the railbed.

Clearance scanner option

The clearance scanner option adds 360 degree coverage for documentation of the cross section around the track.

The clearance scanner is removable and one scanner can be moved between different BV-Scan equipped vehicles.

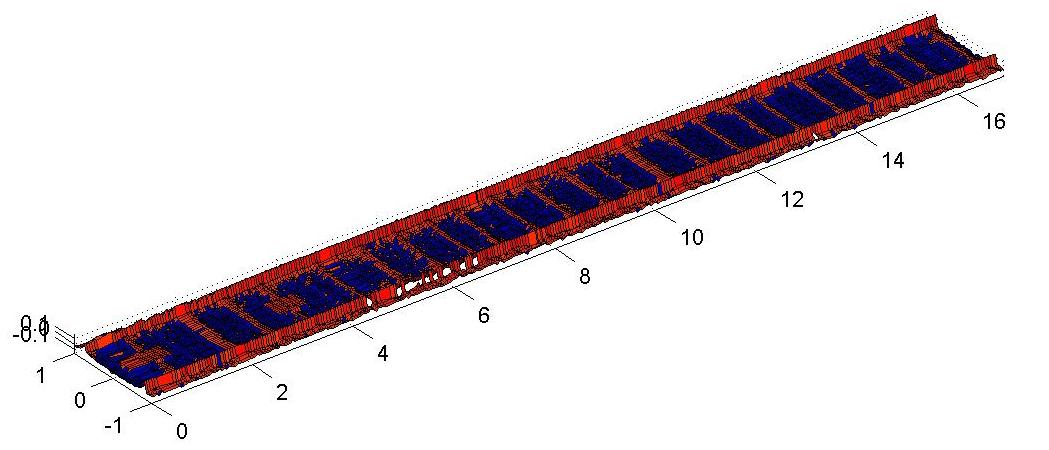

3D track viewer option

BV-Scan with the 3D track viewer option can store high density scans which are used by BVview3D to show the track in a 3D virtual fly through. The 3D image is colour coded to highlight the desired information about the track.

BVview3D makes efficient use of the high resolution data obtained with the high resolution option as well as the 360 degree coverage data obtained with the clearance scanner option.

The BV-Scan advantage

- Robust and reliable! BV-Scan uses weatherproof lasers - we then add our own additional protective casing.

- Cost effective! Compare our prices with any other supplier - we are not worried.

- Easy to use! Basic windows experience is recommended, but we have shown that operators with absolutely no computer experience can learn to use BV-Scan with two days of training.

- Quality! BV-Scan uses high quality components.

- Flexibility! Mobile Robotics is allways prepared to adapt BV-Scan to your needs.

More information

For more information contact MoRoCo AB.